6063-T5/T6 Aluminum Alloy & Advanced Surface Treatment: New Benchmark for Energy-Efficient Doors and Windows

As global green building standards upgrade, 6063-T5/T6 aluminum alloy and premium surface treatment have become core drivers for high-performance doors and windows. Foshan Hannoverwindow’s optimized solutions, backed by authoritative test data, have won wide recognition in the architectural industry for durability, energy efficiency and aesthetics.

The 6063-T5 aluminum alloy, a staple for residential windows, features tensile strength of 150MPa and yield strength of 130MPa, supporting span designs up to 3.2m without deformation. For high-traffic commercial scenarios, 6063-T6 alloy excels with 205MPa tensile strength, boosting impact resistance by 40% and load-bearing capacity by 35% compared to T5 grade.

Surface treatment technologies further enhance performance: 200μm-thick powder coating achieves 1000-hour salt spray corrosion resistance, ensuring 15-year no-fading in strong UV environments; fluorocarbon coating (PVDF) extends corrosion resistance to 3000 hours, ideal for coastal areas. Both treatments reduce maintenance costs by 60% over 10 years.

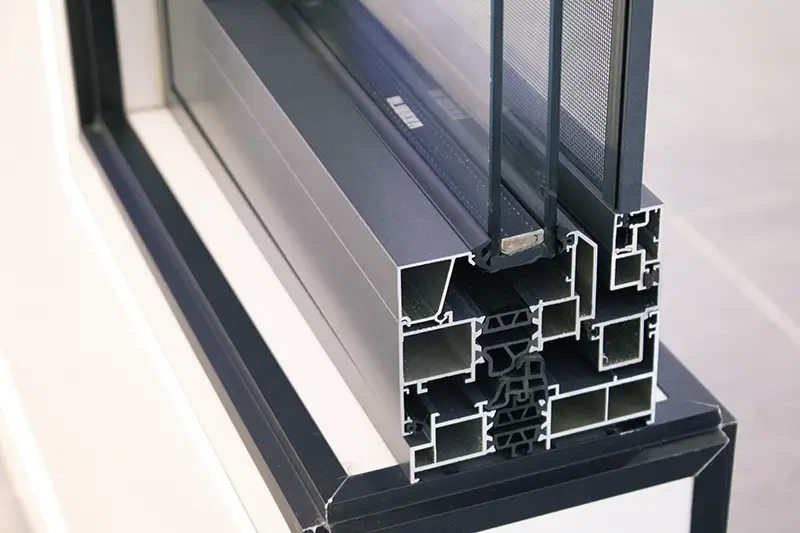

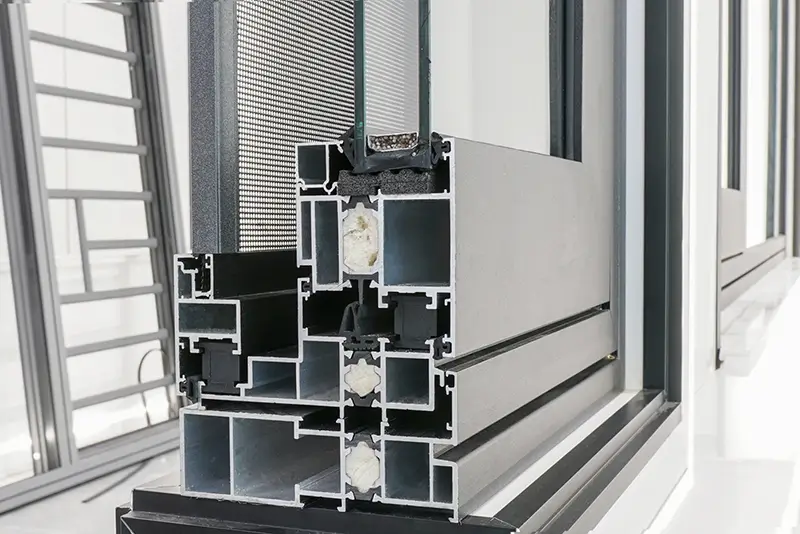

Paired with thermal break technology, the alloy’s 203 W/(m·K) thermal conductivity cuts building energy consumption by 28%. All solutions comply with EU EN 12020 and US AAMA 101 standards. Industry experts note that 6063-T5/T6 alloy’s versatility accelerates the adoption of green building materials globally.

Keywords: 6063-T5 aluminum alloy, 6063-T6 aluminum doors and windows, aluminum surface treatment, powder coating aluminum, PVDF fluorocarbon coating, thermal break aluminum alloy, energy-efficient aluminum windows, EU standard aluminum, corrosion-resistant aluminum frames