3-Layer Insulated Glass vs Bulletproof Glass: Key Differences in Material, Price & Function

3-layer insulated glass and bulletproof glass serve distinct architectural needs, with significant gaps in material composition, cost and performance. Below is a data-backed comparison to guide selection:

1. Material Composition

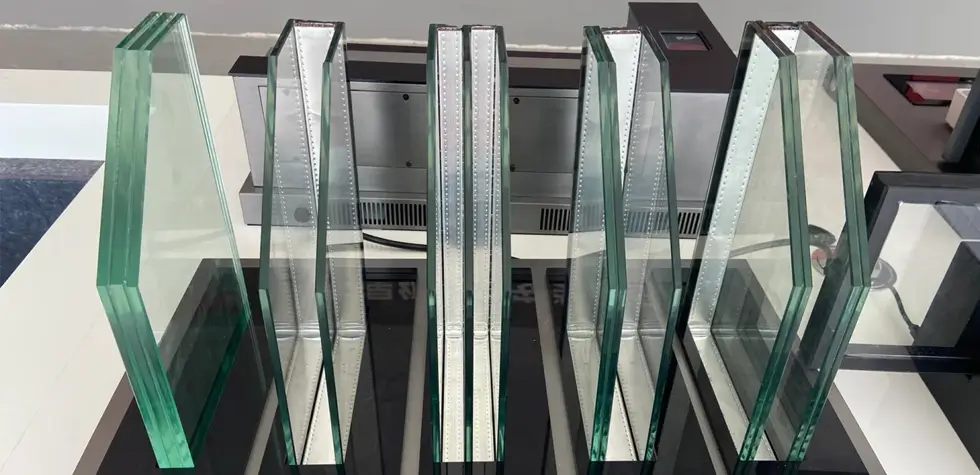

3-layer insulated glass adopts a “glass+dry gas+glass” structure (e.g., 6Low-E+12Ar+6+12Ar+6), with warm edge spacers and sealants, filled with argon for thermal insulation . Bulletproof glass is a composite of multi-layer tempered glass + PVB/PC interlayers, with thickness 20-100mm depending on protection level (BR1-BR7) .

2. Price Range

3-layer insulated glass costs $50-$75 per sqm (400-600 RMB) . Bulletproof glass is 4-10x pricier: basic level (resist 9mm pistol) is $250-$625/sqm, high-level (resist AK47) reaches $935+/sqm .

3. Core Functions

3-layer insulated glass excels in thermal insulation (U-value 1.07-1.33 W/(m²·K)) and sound insulation (reduces noise by 35-45dB) . Bulletproof glass focuses on security, complying with EN 1063 standard, preventing penetration and fragment spatter , with no thermal insulation advantage.

4. Application Scenarios & Target Groups

3-layer insulated glass is widely used in residential buildings, commercial office buildings, and green buildings in cold/hot regions, targeting ordinary homeowners, real estate developers, and green building project parties pursuing energy conservation and living comfort. Bulletproof glass is applied to banks, jewelry stores, government agencies, and high-security villas, serving security directors, financial institution purchasers, and high-end property developers with strict safety requirements.